探索定制盒中袋(BIB)包装的核心优势

Liquid packaging needs to protect the product from oxygen, light, and contamination, survive long-distance transportation, and still look good on a shelf or in a warehouse. At the same time, brands are under pressure to lower freight costs, reduce packaging waste, and make it easy use. That mix of demands is exactly why custom Bag-in-Box (BIB) packaging has become a go-to solution for both bulk liquid packaging and retail liquid packaging.

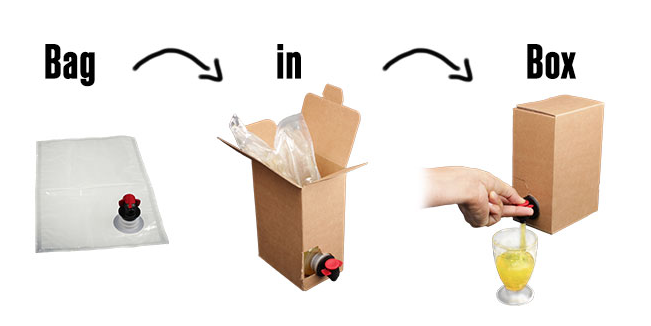

Understanding Bag-in-Box (BIB) Packaging

A well-designed Bag-in-Box is not just a bag inside a carton. It is a complete packaging system made of three parts: an inner bag, a valve, and a corrugated paper box. When these parts are engineered to work together, the result is a liquid packaging solution that is efficient, protective, and versatile. For products such as wine, juice, milk, sauces, and many home and personal care liquids, custom BIB often provides a better balance of protection, cost, and convenience than rigid containers.

Benefits of Using Custom Bag-in-Box (BIB) Packaging Solutions

Better Protection Through an Inner Bag Structure

One of the most valuable advantages of custom BIB is the performance of the inner bag itself. Unlike traditional flexible packaging that relies on a single film structure, LD PACK’s inner bag design uses two layers: an inner single-layer PE film and an outer laminated film. This dual-layer approach provides real-world resilience, particularly for highly fluid liquids that undergo constant internal movement during shipping.

Customization also matters. The outer laminated film can be metallized PET for stronger barrier performance or transparent depending on the packaging requirements of different fillings. That means brands can tailor the bag to the product instead of forcing every liquid into a generic structure.

Stronger Barrier Options for Shelf Life and Product Quality

Many liquids are sensitive to oxygen exposure, light, and aroma loss. Custom Bag-in-Box packaging lets you select multi-layer film structures that match your shelf life goals without overpackaging.

For wine packaging, oxygen control is a constant priority. For juice packaging and dairy packaging like milk, freshness and flavor protection are directly tied to consumer satisfaction. For sauce packaging, barrier performance helps keep color, taste, and viscosity stable.

Leak-Proof Construction That Supports Safer Transport

Damage and leakage are expensive. They create messy warehouses, rejected shipments, and brand complaints. A strong Bag-in-Box system focuses on secure seals, suitable film, and a well-matched dispensing valve.

Custom BIB is designed to be leak-resistant in real shipping conditions because the inner bag is protected inside a corrugated paper box. The outer layer reduces impact, helps prevent punctures, and adds stability for stacking.

Lower Freight and Warehousing Costs With Flat-Packed Efficiency

One of the clearest benefits of Bag-in-Box is logistics. Empty bags and boxes can be stored flat-packed, saving space compared with rigid containers like jerrycans or bottles.

That space-saving turns into real cost reductions:

- Less warehouse area needed for packaging materials

- Lower inbound freight costs for packaging supply

- Better pallet utilization after filling due to strong, stackable cartons

Easier Dispensing With the Right Valve for the Job

Bag-in-Box offers built-in taps or spouts for clean pouring and portion control. LD PACK provides a wide range of valves including butterfly type, screw type, button type, and switch type. This flexibility helps different categories achieve the right user experience:

- Foodservice wine packaging often needs smooth, controlled flow

- Juice packaging for family-size formats prioritizes convenience

- Home and personal care refill packaging needs clean, mess-free refilling

- Bulk formats may require compatibility with semi-automatic filling or fully automatic filling

Stronger Branding and Shelf Presence With Printable Corrugated Boxes

A Bag-in-Box paper box is printable on demand, giving brands space for high-impact graphics, product information, and usage instructions.

Customization can include box size, layout, and structural design. Some brands prefer easy-carry features, while others focus on shelf-facing visuals. For e-commerce, the corrugated paper box adds protection and can reduce the need for extra shipping materials.

A Practical Eco-Friendly Packaging Path Without Sacrificing Performance

Bag-in-Box offers practical environmental advantages in many use cases:

- Less plastic compared with rigid containers

- Recyclable outer box made of corrugated paper

- Potentially lower transport emissions due to better cube efficiency and lighter packaging

For refill packaging in home and personal care, BIB is especially relevant because it helps reduce single-use rigid bottles without changing how the product performs.

Built for Both Bulk and Retail Markets Across Industries

Custom Bag-in-Box keeps growing because it serves very different needs with the same core system.

In food and beverage industry, it fits multiple categories:

- Wine packaging for restaurants, hotels, and events

- Juice packaging for family consumption and institutional use

- Milk packaging for controlled dispensing in kitchens

- Sauces for back-of-house operations and central distribution

In home and personal care, BIB supports:

- Bulk liquid packaging for institutional cleaning products

- Refill packaging that reduces waste

- Efficient dispensing for high-frequency liquids like soap or detergent

Why LD PACK Is an Ideal Partner for Your Custom BIB Projects?

Custom packaging works best when the supplier understands both material performance and filling realities. LD PACK’s Bag-in-Box solution is built around the full system: inner bag, valve, and outer corrugated paper box, with the flexibility to adapt designs to different products and production setups.

Key strengths you can expect from LD PACK include:

- Two-layer inner bag design with inner single-layer PE film and outer laminated film

- Film options including metallized PET or transparent structures

- Supply formats such as single bags or continuous bags in rolls

- A wide selection of valves for manual, semi-automatic filling, or fully automatic filling

- Printable corrugated paper boxes for branding and instructions

- Options for standard and custom structures, including mono-material PE

Custom Bag-in-Box Packaging Solutions

Conclusion: Customize Your Bag-in-Box Packaging at LD PACK

Custom Bag-in-Box packaging is a practical answer to modern liquid packaging challenges. It protects products through a dual-layer inner bag structure, supports shelf life with multi-layer film options, simplifies dispensing with tailored valve choices, and reduces storage and freight costs thanks to flat-packed efficiency. It also offers a clear path toward eco-friendly packaging through less plastic and a recyclable corrugated outer carton, plus optional mono-material PE structures.

If you are looking to upgrade packaging for wine, juice, milk, sauce, or home and personal care refill packaging, LD PACK can help you build a Bag-in-Box solution that fits your product, your filling process, and your market. With customizable bags, valves, and printed boxes, LD PACK delivers a reliable, cost-effective liquid packaging solution designed for both bulk and retail success.